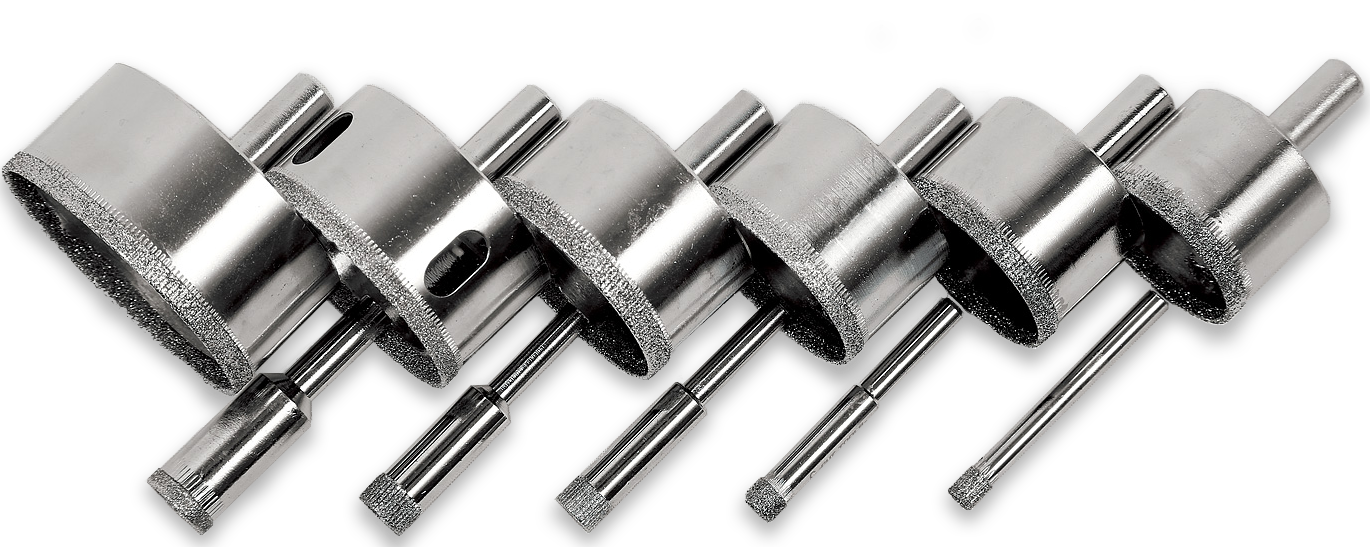

Welcome to C-Cut Tools, the home of the Diamond Coated Hole Saw™

We are the manufacturers of the Diamond Coated Hole Saw™ product range, a unique saw on the market with powerful cutting abilities.

The Diamond Coated Hole Saw™ products cut faster and cleaner than any other tool or hole saw available.